Maglev Vehicle

MA State Science Fair - 2018

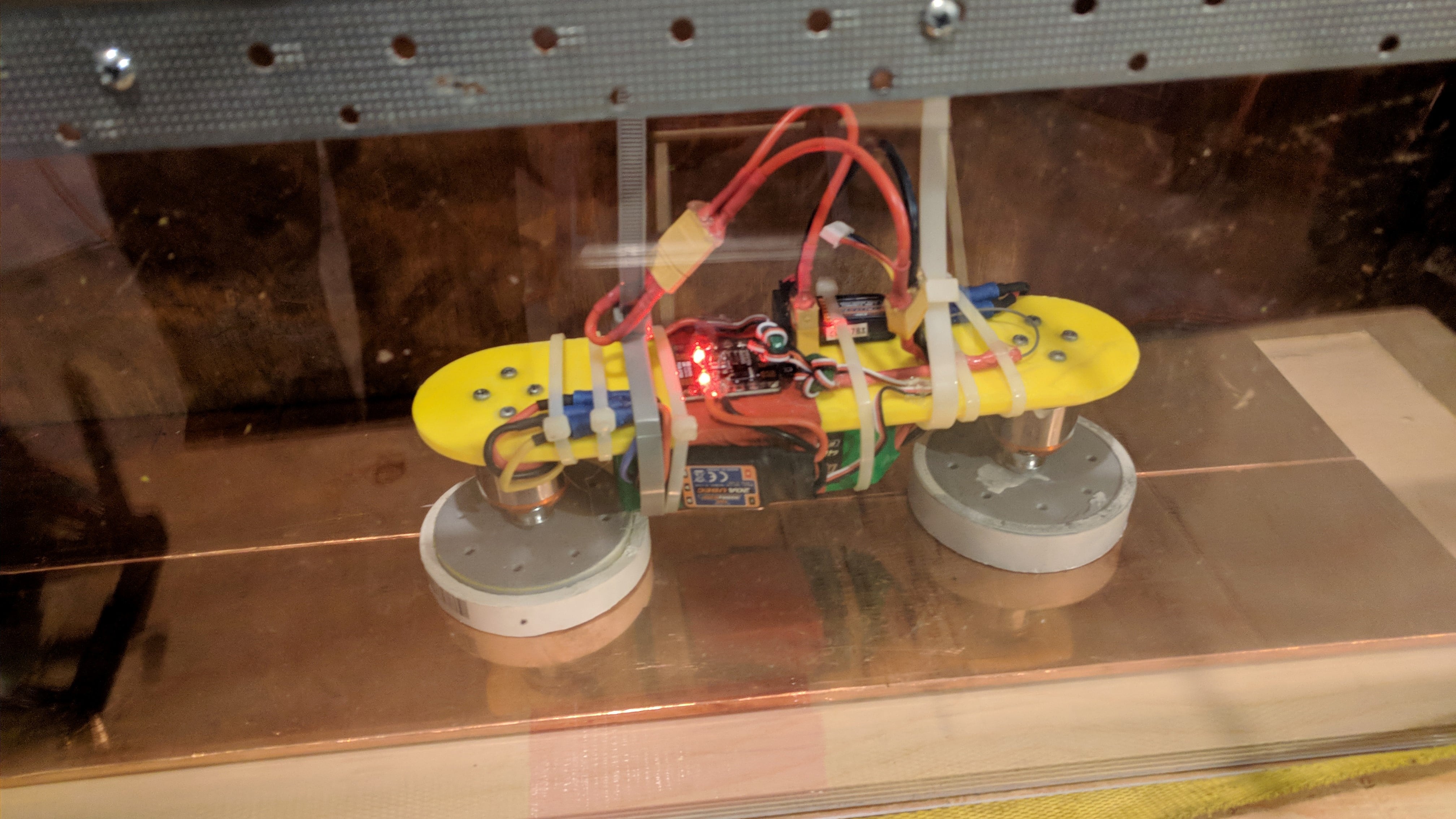

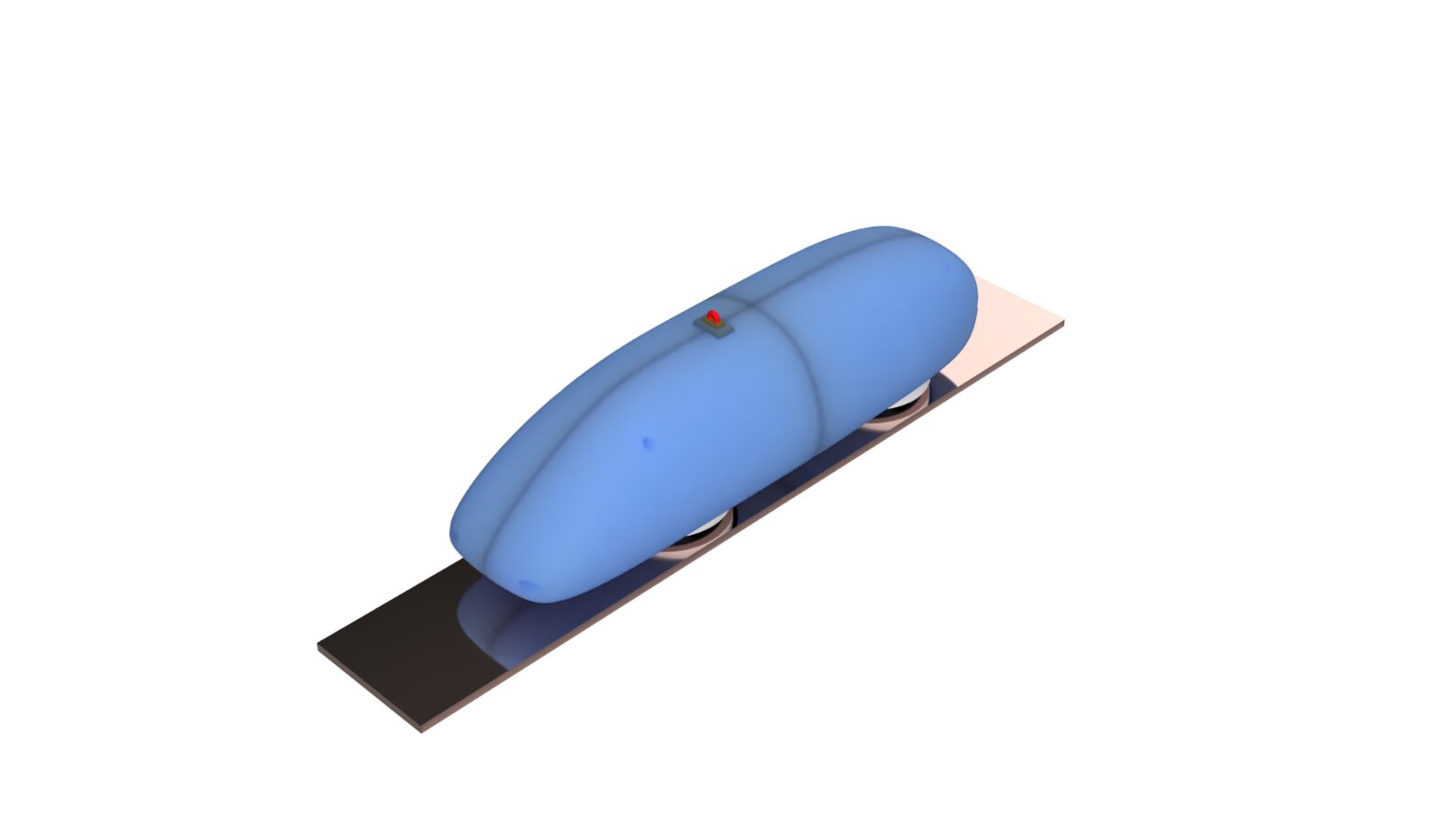

For my science fair project in my senior year of high school I designed and built a magnetically levitating test vehicle. I researched various methods of magnetic levitation, and settled on an Inductrack design, spinning disk arrays of magnets over a copper track. I also used an arrangement of magnets called a halbach array to increase the strength of the arrays, and therefore increase the lifting force.

I designed all the parts in Autodesk Fusion 360, and printed them with my school’s MakerBot 3D printers. The electronics powering the project were the same as those used in quadcopters, so I purchased all required components, and performed all the soldering and other assembly.

During testing of my initial designs, the 3D prints failed catastrophically as I, having little experience with 3D printing at the time, had not adequately reinforced the prints to handle the forces and vibrations involved. This incident proved to be a learning experience for me, and I gained a lot of knowledge about how to better strengthen 3D prints, as well as parts in general.

I developed a second design, using the components that were not damaged by the initial failure, and testing showed that the vehicle could produce 9.4 lbs of lift, in a vehicle weighing just over 3 lbs. I took this project to my local science fair, earning a first-place prize, my regional science fair, earning a third-place prize, and finally to the Massachusetts State Science and Engineering Fair, where I earned an honorable mention award.

As a part of this project, I used and developed my skills in engineering design, Autodesk Fusion 360, additive manufacturing, and electronic assembly.